TIGHTVIEW® Proximity System Applications

Metrix now produces a proximity probe system that can fit in very tight spaces and provide an excellent linear measurement compared to competitive products for similar applications.

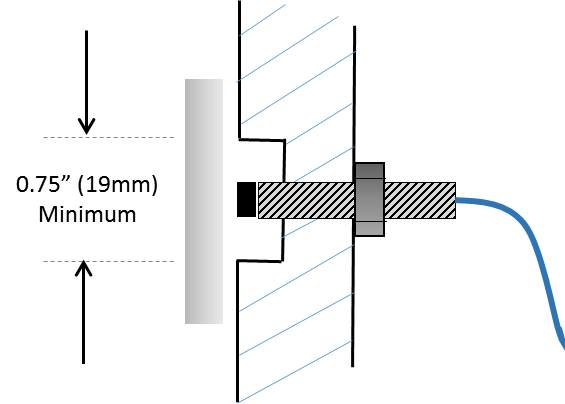

Normal proximity probes usually need at least their probe tip diameter as clearance around the probe tip to ensure an accurate measurement. The above counter bore dimensions, 0.75” (19mm), are typical for a proximity probe to ensure there is no side interference at the probe tip.

Click here to download TIGHTVIEW® Proximity System Application Note.

With the Metrix TIGHTVIEW® System, counter bores as small as 0.375” (9mm) can be used and still meet the API 670 linear range and accuracy requirement. Also, with obstructions that are as tight as 0.05” (1.3mm) from one side of the probe, the API 670 linear range and accuracy can also be achieved.

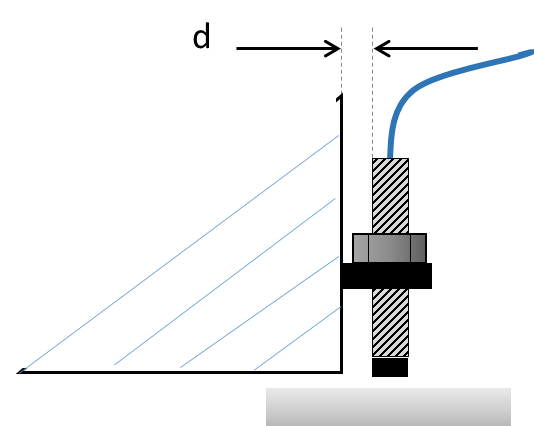

Counter Bore

"d" to 0.375 inches (9mm)

Using Metrix MX8030 5mm or 8mm Probes

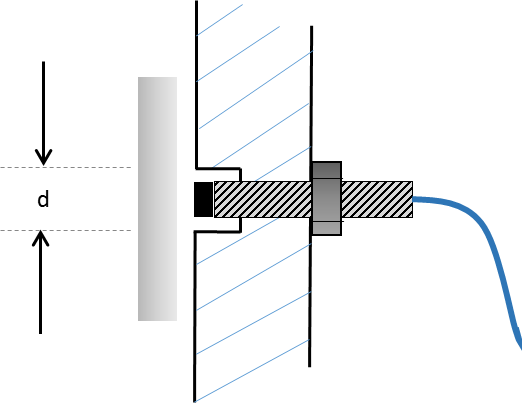

Obstructed Side View

“d” to 0.05 inches (1.3mm)