Water Treatment Plants

Water Treatment Plant Overview

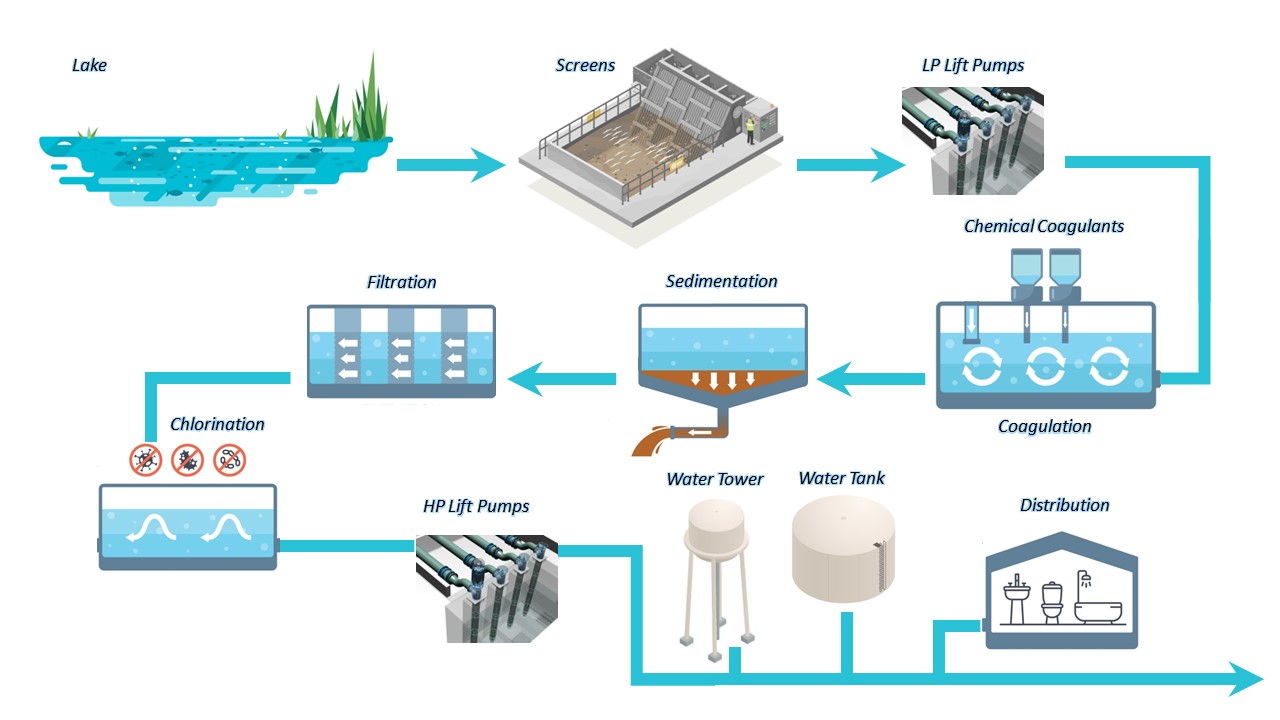

Water Treatment Plants are facilities that treat water to make it safe for human consumption and other uses. The process of water treatment involves several steps that remove impurities and contaminants from the water. Usually, gravity is used to help convey the water to the treatment plant, in many cases lift pumps need to be used to move the water from a lake or river to where the water can be treated in a treatment facility. The size of the lift pumps is determined by the flow volume and the pressure head necessary to deliver the water. The bearings for the lift pumps are either going to be Rolling Element Bearings or Fluid Film Bearings depending upon the size of the pump. Large pumps, over 1 megawatt, usually have Fluid Film Bearings.

Figure – Typical Water Treatment

In the water treatment process, the first step is to remove any physical objects and large particles from the stream. This starts in a screening process and may involve conveyors. The conveyor motors should be monitored with velocity transmitters on the load side bearing to help ensure that the debris does not cause a problem with the conveyor. The next step is to remove the dissolved solids suspended in the water. To speed up the settling and removal process, chemicals called coagulants are added to the water. The most common coagulant is aluminum sulfate, but this varies by the Water Treatment Plant. Essentially this chemical has the opposite charge from the suspended solids, like clays or silts, which then neutralizes the charge and allows for the particles to stick together. In the coagulation basin the solids in the water begin sticking together, the mixture is slowly mixed and moves to the flocculation basin in order to continue to form what are called floc particles. The motors for the coagulation and the flocculation mixers are slow moving, usually, rolling element bearing machines. These machines should be monitored per the Hydraulic Institutes Guidelines 9.6.4 for machines operating less than 600 rpm, using seismic velocity transmitters measuring vibration velocity and integrated displacement.

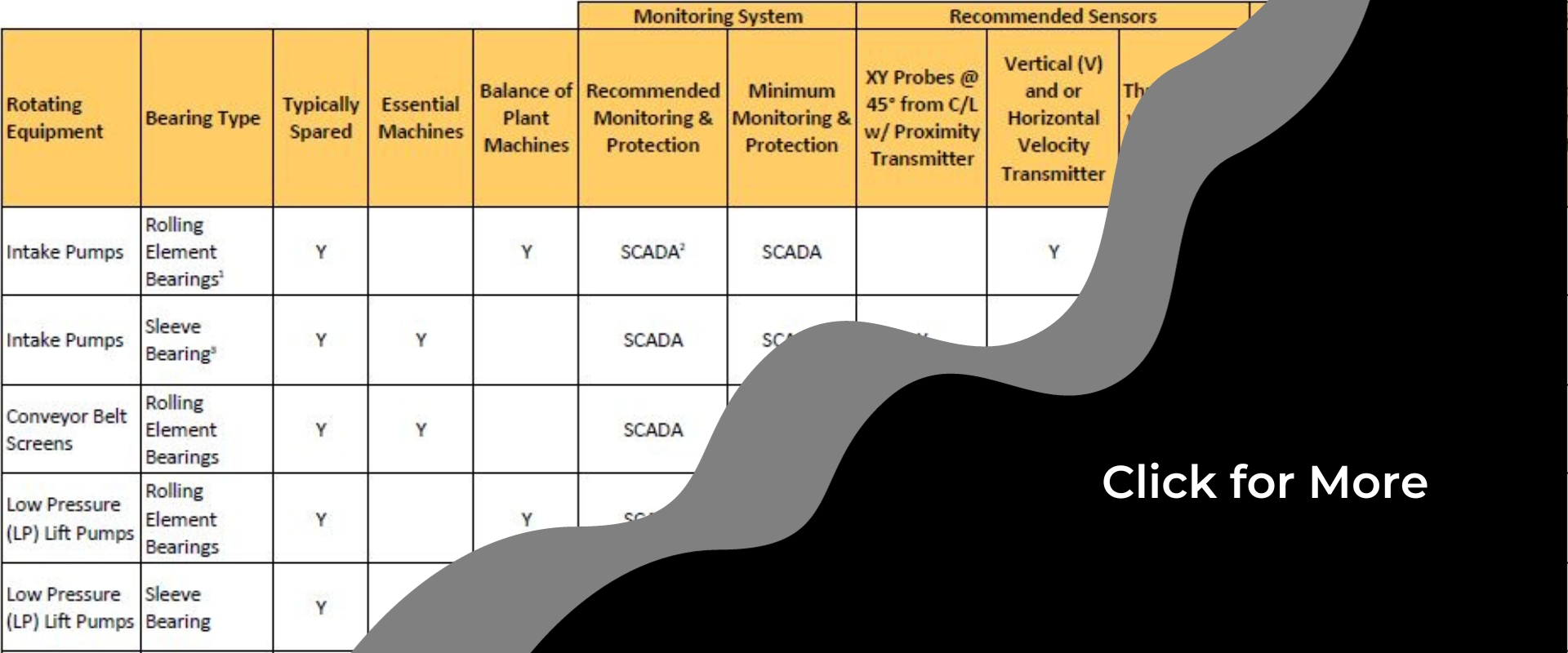

Monitoring the vibration allows for any degradation to be noticed, and maintenance to be planned in advance of machine failure (see the tables below for monitoring recommendations). The floc particles then settle out of the mixture in a sedimentation basin, and cleaner water flows overtop a weir. This process is only the first step, and it has mainly removed larger particles in the water, but some smaller particles may remain, as well as chemicals and bacteria. Following sedimentation, the next step is typically filtration through a sand filter. Sand filters have been used since the beginning of water treatment, and they are required most everywhere to be included in the treatment process to assure a standard level of clarity.

Sand filters are used as a step in the water treatment process of water purification. There are three main types; rapid (gravity) sand filters, upward flow sand filters and slow sand filters. All three methods are used extensively in the water industry throughout the world. Sand filtration works by using multiple layers of specialized sand and gravitational fluid pressure to retain solid particles suspended in liquids, resulting in a cleaner product. As fluids pass slowly though layered sand and gravel beds, natural physical, biological, and chemical processes combine to provide treatment. Gravity is often used to move the water through the sand filter beds, however, is some higher flow or demand situations, pumps are often used to force the flow through the beds. Pumps are also used to force water to back flush the beds to clean them and allow for their continued use. These pumps are usually employing rolling element bearings and are monitored with velocity transmitters. On larger pumps, greater than 1 megawatt, fluid film bearings are used necessitating the need for proximity sensors for proper monitoring.

It should be noted that, anthracite is a type of coal that is used in water filtration systems. It is used as a filter medium in dual media filters with sand as the other medium. Anthracite is used to remove smaller particles from water than sand alone can remove. At the end of the process chlorine is added as a disinfectant, it kills any organisms that have not been removed in the filtration process.

Tables – Water Treatment Rotating Machine Monitoring Recommendations

Wastewater Treatment Plants clean sewage and water so that they can be repurposed for our use.

Pumps play a vital role in vibration monitoring in water and wastewater treatment plants.

Download our Water Treatment Whitepaper Download our Water Treatment Brochure