Vibration Monitoring Solutions Catalog

Reliable, highly sensitive vibration monitoring is essential across numerous industries. A quality control system that utilizes vibration monitoring can ensure that industrial equipment is securely mounted and running efficiently. This vibration-based process monitoring is especially critical for operations that put a great deal of wear and tear on their high-value equipment, such as pumps and compressors that run around the clock.

If your operation relies on pumps, compressors, fans, turbines, or motors, a robust, responsive, end-to-end vibration monitoring solution from Metrix can save downtime, improve operational efficiency, and protect your most valuable equipment, while providing early warning of any impending failure.

A high-quality vibration monitoring system supports your day-to-day operations in a variety of ways:

- Monitors the operation of rotating and reciprocating machinery.

- Detects wear and tear before larger issues occur, reducing downtime and protecting machinery.

- Collects detailed condition monitoring data allowing you to improve the scheduling of maintenance cycles.

- Protects your equipment and employees by noticing emerging issues before they lead to catastrophic failures.

- Ensures your equipment and processes are running within specification

Metrix Vibration has been providing our partners with innovative vibration monitoring equipment using accurate and reliable sensors for over half a century. Some of the products we work with include seismic vibration sensor systems, proximity vibration monitoring solutions, and industrial components like vibration switches and high-temperature velocity sensors for use in high-end custom applications.

Browse our vibration monitoring equipment online today:

Metrix has revolutionized the industry with our Digital Proximity System (DPS). A user is able to support a multitude of cable lengths, target materials and older probe systems with just a single device. Our Digital Proximity System combines the performance of a fully API 670 compliant eddy-current proximity measurement system with the flexibility of digital configurability. DPS saves our customers time and money.

Seismic vibration detection systems are often used by process industries, oil & gas, power generation, water and wastewater, construction, civil and mechanical engineering, and scientific research communities. Seismic vibration instrumentation measures casing vibration on bearing housings, machinery housings, and machine support structures, including piping. They are particularly suitable for machinery with rolling-element bearings and reciprocating compressors. These types of bearings will generally transmit both rotor and bearing-related vibration to the outside of the machine, where seismic measurements can detect it.

A vibration switch is a special type of electronic switch that is triggered on or off when a certain pre-defined level of vibration has been measured. Such switches can be configured into simple alarms to alert you when a machine has gone out of tolerance or used as elements to shut down a machine in more complex custom monitoring and automation systems.

At Metrix Vibration, we offer top-of-the-line electronic and mechanical vibration switches for overall vibration monitoring and trending without the need for complex systems. We aim to be your preferred vibration switch manufacturer and supplier for any industry, and our goal is always to keep you and your business safe and productive. We offer models with Hazardous Area Ratings and explosion-proof housings to ensure your production lines stay safe. Our state-of-the-art electronic switches are configurable to suit user needs.

The Hardy Shaker ensures that our Seismic Sensors and Transmitters work properly and give you the results you need. Just like the pressure and flow instruments in your facility require calibration checks every year, so do your Seismic Sensors and Transmitters.

This system puts the calibration check of Seismic Sensors and Transmitters in your control. As a cost-effective maintenance strategy, this predictive and proactive approach is better than a run-to-failure strategy. The entire premise of a predictive and proactive maintenance program is based on the reliability and integrity of the transducers providing the information.

If the Seismic transducers are not working properly, you will not receive the value you are expecting to produce the return on investment that you have already made. The Hardy Shaker is necessary to ensure your proactive maintenance strategy is effective. The Hardy Shaker comes in two models - HI-903 and HI-913 for your convenience.

Portable vibration equipment allows you to quickly check the overall vibration of a machine whenever you want to, or to check the condition of a sensor or transmitter with one of our shakers. Overall vibration or technically direct amplitude is a measure of the severity of the vibration. Many people and many standards organizations attribute increasing vibration levels to machine degradation or other machines problems like unbalance or misalignment. At Metrix we teach that changing vibration levels from a normal condition is what should be concerning. Vibration levels going up or down significantly from normal should cause concern, not just increasing vibration levels. Having confidence in your portable data collection equipment and any permanently installed vibration monitoring equipment is paramount to an effective condition monitoring program. The portable vibration meters below, as well as the shakers, are integral to an effective predictive and or proactive maintenance program.

Vibration monitors provide technicians with local display, alarm and shutdown capability, and using Datawatch, one can have data recording functionality. Metrix’s monitors have the ability to communicate effectively using a 4-20 mA output and, with Datawatch, Modbus over Ethernet TCP/IP. If you need to trend waveform and transient data to provide a predictive look at your machine’s condition, Metrix can provide the sensor solution that can meet your machinery monitoring requirements.

At Metrix, you’ll find an array of equipment monitors, all of which generate accurate and reliable data. The key to choosing the right one for you, whether you operate in energy, wastewater treatment, manufacturing, or in oil and gas process industries, is finding the right monitoring equipment for your application.

What Are the Benefits of High-Precision Vibration Monitors?

Metrix’s vibration monitors are designed to add value to a company's bottom line. Each product can save a company time, money, and frustration when implemented correctly. When you choose our equipment, you can expect the following benefits:

● Reduce false alarms: Reliable monitoring equipment is remarkably accurate at determining machinery vibration and providing early warning to prevent breakdown. So, if you're tired of having to turn off vibration equipment when a machine starts up (because the initial vibrations trigger the alarm), you can configure the settings so that's not an issue anymore.

● Predictive maintenance: Monitoring equipment helps technicians schedule maintenance based on the rhythms and patterns of each machine. This benefit can rule out the possibility of over- or under-servicing your machinery.

● Increased production: Not only can monitoring equipment extend the machine’s lifespan, but it can also lead to optimized performance of the site’s equipment (and your productivity numbers).

● Reduced risk: From employee safety to unplanned downtime, companies can drastically reduce liability by continuously monitoring the vibration of their machines.

● Energy-efficiency: An optimized machine will run smoothly and use less energy. Energy-efficiency not only lowers a company’s utility bills, but it can help a company stay within their industry’s compliance regulations.

Metrix’s Vibration Monitoring Systems

The vibration sensing devices from Metrix are versatile enough to fit the needs of different industries. The displays are easy to read and accurate. In addition, they’re flexible enough to adapt to different applications. For instance, using the SW55580, one can measure two vibration points, or you can put three units together to obtain six data points. Using the Datawatch, you can monitor up to eight data points. If you need to measure up to 16 vibration points, then you just need to add another Datawatch. If you need to add channels, you can stack the devices together to fit the needs of your equipment. Each monitor and switch have undergone lengthy iterations to provide more access and functionality across industries.

AM3030 Single Channel Alarm Monitor

The AM3030 Single Channel Alarm Monitor has a bar graph display in three colors. It features up to four programmable trip points, conveniently boxed up in a ⅛ DIN package. Technicians and engineers can quickly determine the excitation levels sent from vibration transmitters in a simple, easy-to-read device. The AM3030 accepts 4-20 mA current inputs and is configured by the 5 front panel keys. It's available in both analog and serial retransmission.

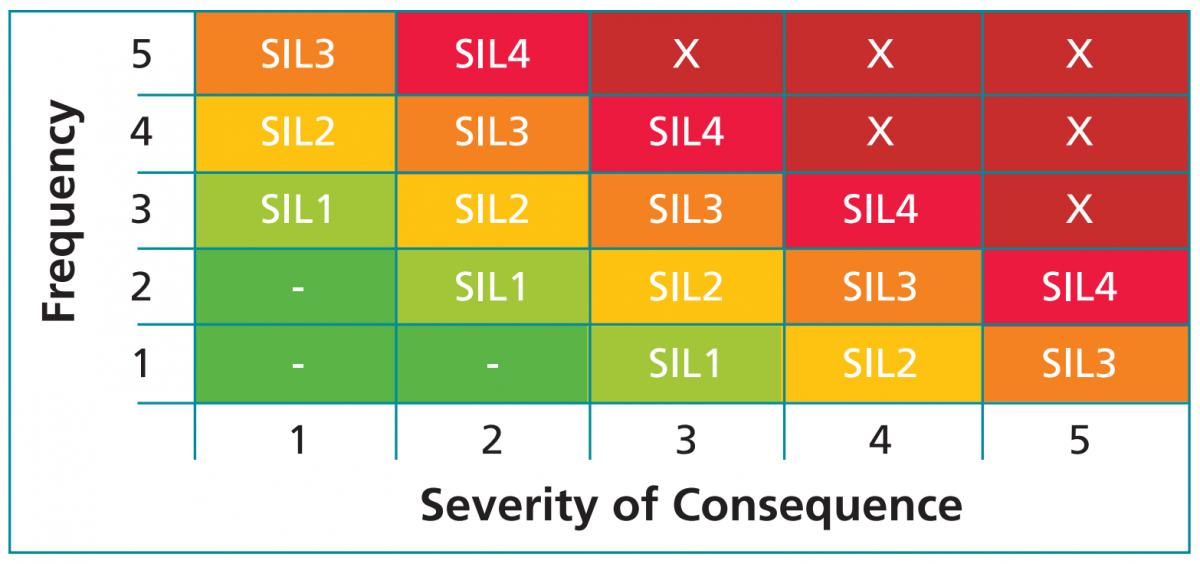

SIL (Safety Integrity Level) is a method or measurement unit to determine the reliability of electrical, electronic and programmable systems. Our products were thoroughly evaluated by a third party agency on the basis of IEC61508 Functional Safety standards to obtain the SIL certifications.

The assessments cover the areas of systematic capability, hardware safety integrity and random safety integrity. Achieving SIL certification signifies that the product has been thoroughly assessed and is a reliable electronic device ready to use across a wide range of industries.

These products are no longer in production but have been replaced by new and updated products.

- 5510C/5516C, 5534/5544, 5535/5545 Obsolescence and Replacement Plan

- 5535, 5545 Velocity Signal Conditioner - Replaced by 5580 Signal Conditioner

- 5534, 5544 Velocity Signal Conditioner - Replaced by 5580 Signal Conditioner

- 5516C Signal Conditioners - Replaced by 5580 Signal Conditioner

- 5510C Signal Conditioners - Replaced by 5580 Signal Conditioner

- SA6200 Accelerometer - Replaced by SA6200A Accelerometer

- MX3309 Probes & Cables - Replaced by MX8030 Probes and MX8031 Cables

- MX3300 Probes & Cables - Replaced by MX8030 Probes and MX8031 Cables

- HI-813 Hardy Shaker - Replaced by HI-913 Hardy Shaker

- HI-803 Hardy Shaker- Discontinued on December 31, 2018 - Replaced by HI-903 Hardy Shaker

- TXR 5521 RPM Transmitter - Discontinued on December 31, 2017 - Replaced by MX2034 DPS Transmitter

- TXR Transmitter - Discontinued on December 31, 2017 - Replaced by MX2034 DPS Transmitter

- TXA Transmitter - Discontinued on December 31, 2017 - Replaced by MX2034 DPS Transmitter

- 5533 Probe Driver - Replaced by MX2033 DPS Driver

- SH2000 Pocket-Sized Vibration Meter - Replaced by VM2800 & VM3800 Vibra-Check meters