Metrix Blog

Blog Posts

Advantages of Portable Vibration Monitoring Equipment

Discover the benefits of portable vibration monitoring equipment, including flexibility, ease of use, and real-time data collection for efficient maintenance.

Read More..

Vibration Monitoring in Reciprocating Compressors

Discover how vibration monitoring can help optimize reciprocating compressor performance. Learn key monitoring techniques and predictive maintenance strategies for efficient operations of reciprocating compressors.

Read More..

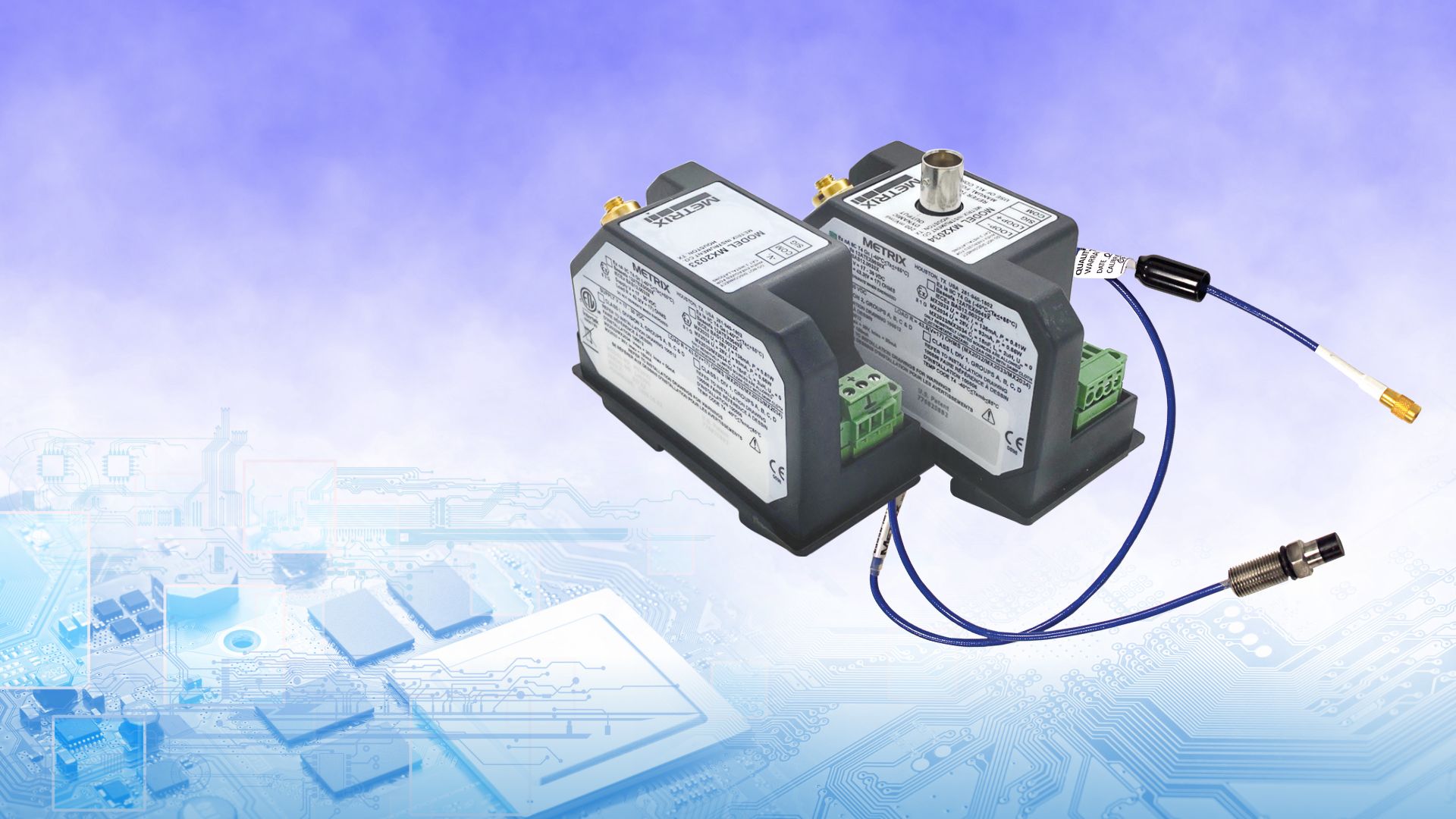

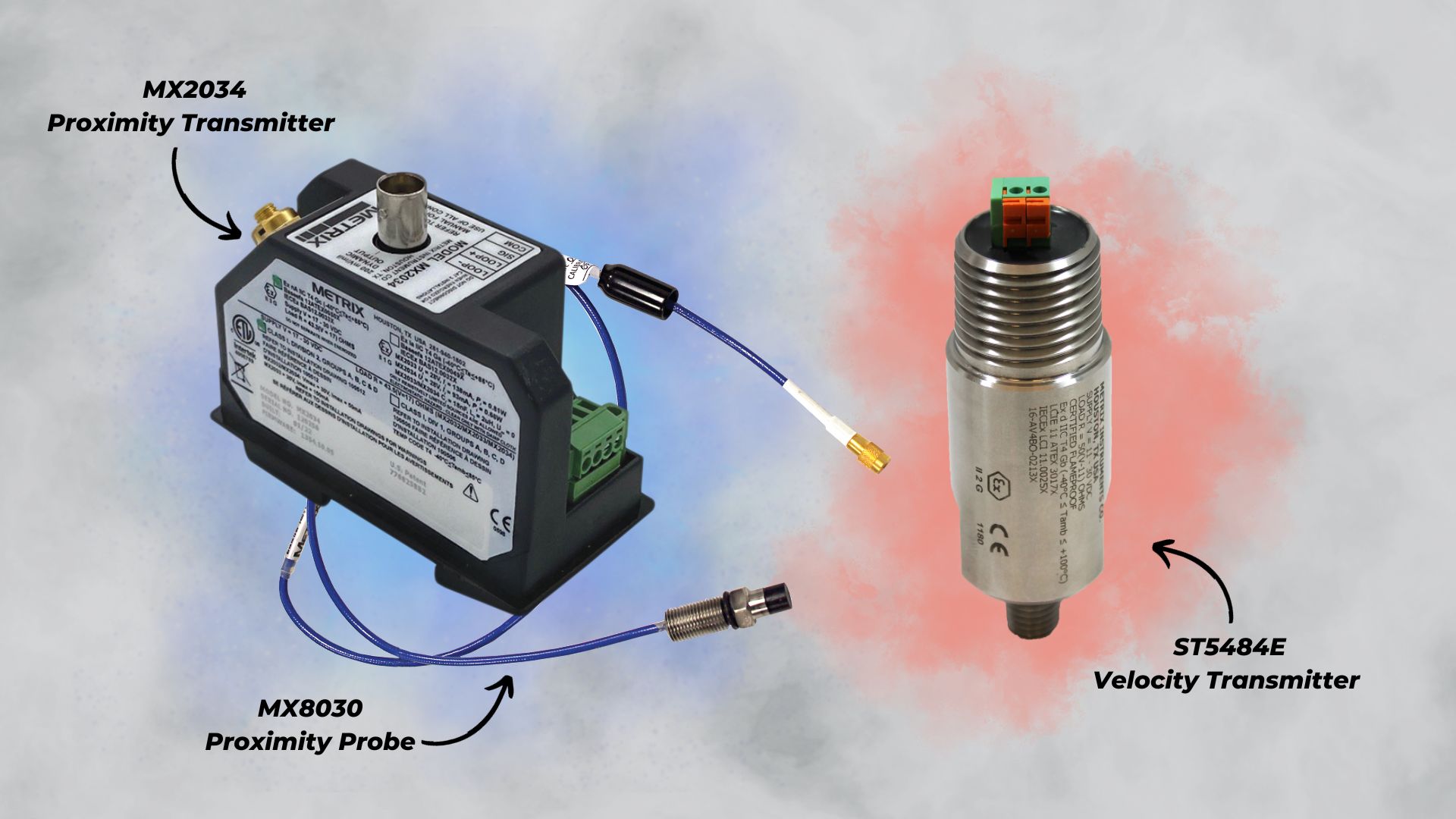

Proximity Probes and Seismic Sensors

Compare proximity probes and seismic sensors for vibration measurement. Learn key differences, applications, and how to choose the right product for your rotating machinery.

Read More..

Enhancing Efficiency Wastewater Treatment Operations

Learn about advanced real-time monitoring solutions and how our sensors can enable you to optimize machinery performance.

Read More..

Proximity Vibration Monitoring for Critical Machinery

Explore the advantages of proximity vibration monitoring for critical machinery. Understand how this technology reduces unscheduled downtime and ensures safety of plant personnel.

Read More..

Best Practices for Pump and Motor Monitoring

Learn more about the importance of pump and motor condition monitoring. We will discuss maintenance strategies and give you a real-world example.

Read More..

Regular Calibration for Proximity Vibration Monitoring

Learn the importance of periodic calibration checks for proximity systems to ensure accurate measurements, enhanced reliability, and more.

Read More..

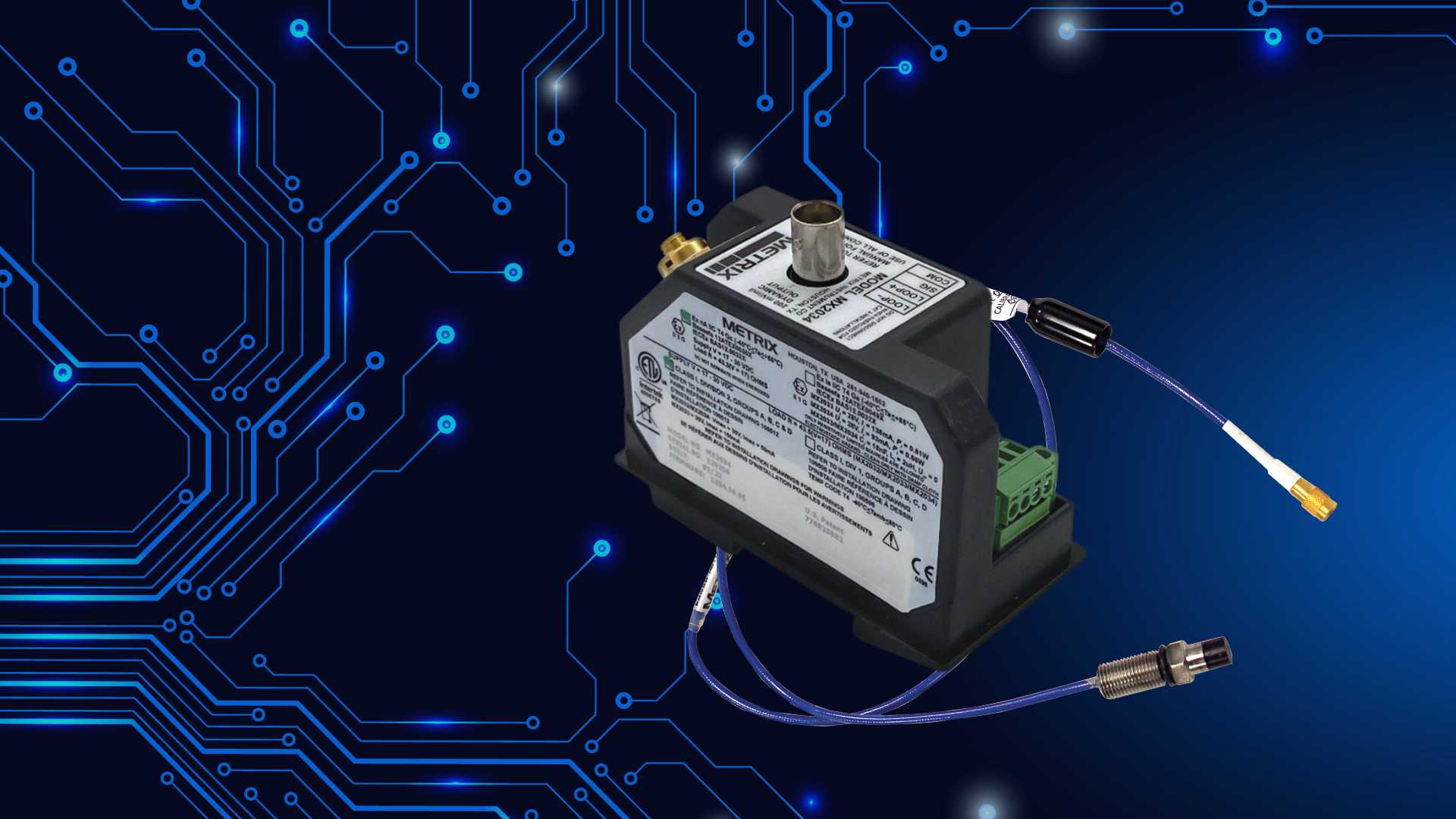

Digital Proximity Systems Improve Reliability

Proximity Systems across different industries improve reliability of Rotating and Reciprocating Machinery.

Read More..

The Future of Seismic Sensors in the Vibration Monitoring Industry

Let's take a dive into seismic sensors and their benefits across various industries. What does the future hold for accelerometers and velocity sensors?

Read More..

Seismic Sensors in Predictive Maintenance

Explore the pivotal role of seismic sensors in the realm of predictive maintenance. Learn how these cutting-edge technologies enhance early fault detection.

Read More..

The Latest Developments in Proximity Systems

Stay ahead with the latest advancements in digital proximity systems. Discover the key insights, trends, and applications shaping this innovative technology.

Read More..

How to Choose the Right Seismic Sensor

In this blog post, we are discussing seismic sensors, which typically means we’re talking about machines with rolling element bearings. Read on to learn about how to choose the right seismic sensor for your needs.

Read More..

The Advantages of Digital Proximity Systems for Vibration Monitoring

Explore the benefits of digital proximity systems, from early detection of machinery faults to proactive maintenance strategies.

Read More..

The Fundamentals of Signal Conditioning and Vibration Monitoring

Discover the benefits of implementing signal conditioning solutions to optimize the performance of a wide range of vibration monitoring applications.

Read More..

Resonance and Vibration

What is resonance? What is vibration? We’ll look at these concepts, the relationship between them, and what it ultimately means for your machinery assets.

Read More..

The Fundamentals of Measuring Vibration

The purpose of measuring vibration is to obtain a picture into how the machine is operating. Here's all you need to know.

Read More..

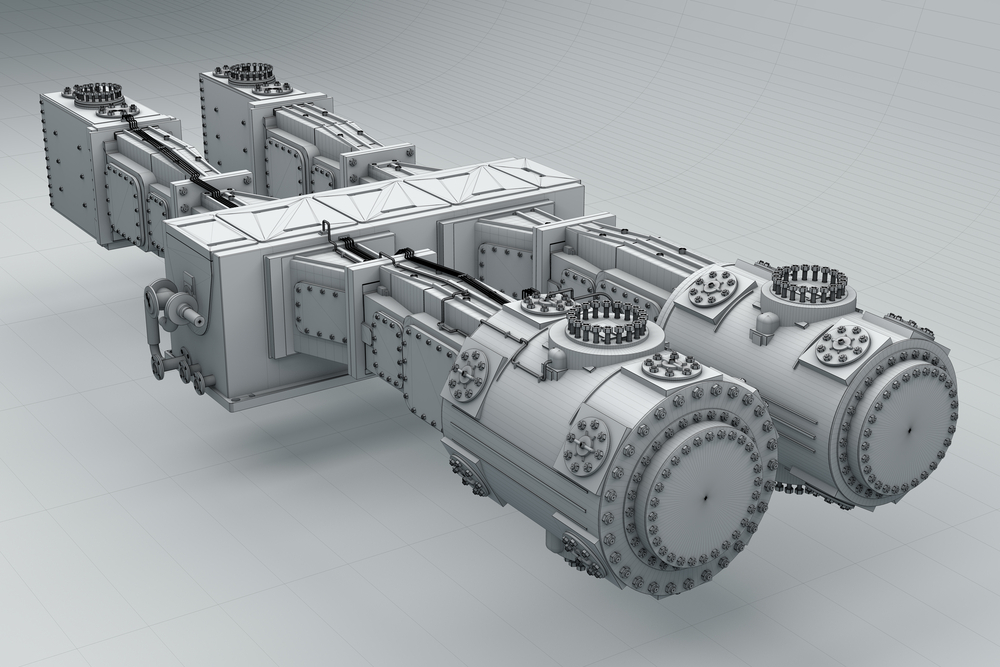

Monitoring Your IGC Compressor

Learn the essentials of effectively monitoring your IGC compressor with our comprehensive guide. Learn crucial tips and techniques to ensure efficiency and reliability.

Read More..

Premium Vibration Transmitters from Metrix

Discover the benefits and reliability of vibration transmitters from Metrix. Improve overall efficiency and protect your valuable equipment with our transmitters.

Read More..

How Vibration Monitoring Can Extend the Life of Your Pumps

By implementing a remote monitoring system for your pumps, you can increase their life expectancy and keep them running smoothly for longer. Read our new blog post to learn more.

Read More..

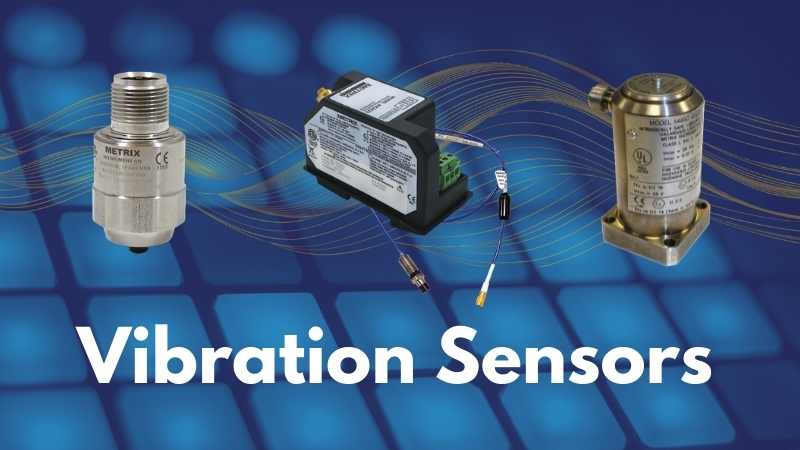

How to Choose Vibration Sensors or Transmitters

Are you familiar with the different types of vibration sensors or transmitters for rotating or reciprocating equipment? Learn which type of vibration monitoring equipment will benefit your plant.

Read More..

Monitoring Your Reciprocating Compressor

Learn about reciprocating compressors, the different types, and how to maintain them to their fullest capacity.

Read More..

Seismic Monitoring: Vibration Detection of Machine Condition

Seismic monitoring systems are a valuable tool for machine maintenance and reliability, enabling the early detection of mechanical problems and optimization of process performance. Read our new blog post to learn more.

Read More..

When Control Systems Should Be Used as Vibration Protection Systems

When should you choose a transmitter vibration monitoring methodology in lieu of a permanently rack based vibration monitoring solution?

Read More..

Proximity Monitoring for Machines - Touchless Detection of Issues

Learn about proximity probes and how they are used to monitor machine conditions.

Read More..

Condition Monitoring Sensors

Learn about condition monitoring sensors, their various types, and how they can accomplish the primary goal of ensuring that the process and the machines continue to work properly.

Read More..

Vibration Monitoring of Cooling Towers

Read our blog post to learn about vibration monitoring of cooling towers and how seismic sensors come into play.

Read More..

What is Condition Based Maintenance?

Condition based maintenance is one of four ways to manage rotating and reciprocating machines at a plant. Read further to learn more about the methodologies that are used at a plant to manage and operate machinery.

Read More..

Selecting a Signal Conditioner

When it comes to monitoring vibration, signal conditioners are an important tool. By understanding the different types, you can choose the right one for your needs.

Read More..

Basics of Vibration Analysis

Vibration switches are a critical component to help keep your machines in proper working order. They help protect the machine, while providing you an opportunity to conduct vibration analysis when needed. This saves you time and money.

Read More..

How to Use Seismic Transmitters & Switches

Learn how vibration monitoring using seismic sensors can help reduce the duration of unscheduled downtime which results in quality operations, expediting repairs, remediating safety concerns, and improving delivery.

Read More..

Which Sensors Detect Vibration in Machinery

When it comes to rotating and reciprocating machinery, minor problems can quickly arise. Learn which sensors detect vibration early to take proactive action.

Read More..

Which Vibration Detection Device To Use

You might need to use either an accelerometer or a velocity sensor in various circumstances to detect vibration. Which one you decide to use will depend on the data you're trying to capture and monitor.

Read More..

Top Benefits of Vibration Monitoring

Is Vibration Monitoring really important? Click to learn about the top 5 benefits of vibration monitoring to improve the efficiency of your company!

Read More..

How to Use Accelerometers to Measure Vibration

Wondering about accelerometers and how to use them? Learn more about the types of accelerometers, how they can monitor various machines, and more.

Read More..

What is a Vibration Monitoring System?

Want to learn more about vibration monitoring systems? In this blog post, we’ll walk you through the basics, along with how they work and the benefits they offer.