The Latest Developments in Proximity Systems: What You Need to Know

With advancements in technology, digital proximity systems keep evolving.

Like all technology, proximity systems have come a long way in monitoring rotating and reciprocating machinery. Proximity systems used in vibration monitoring started when Don Bently pioneered the first linear system in the late 1950’s. His proximity system was able to measure accurately down to thousandths of an inch. Modifications have been made through the years to improve accuracy, linearity, and repeatability. His analog design still works to this day, but it is very stringent on material type, probe size and type, and system length. In other words, you were pretty much stuck with what you ordered. If you had a proximity system that was designed for 4140 target material, had an 8-mm probe tip and a 5-meter system length, that is how you had to use it. If you needed it for a 17-4 pH stainless steel rotor, the system won’t work properly. Accommodations could be made in the Vibration Monitoring System (VMS), but only for the Average Scale Factor (ASF) of the system. The system would not meet the Incremental Scale Factor (ISF) requirements of API 670. Things have changed radically over the past decade. We'll look at the changes, as well as the real-world examples of companies that have put the new capabilities to the test.

Why a Digital Proximity System

Why would anyone want to take a perfectly good analog signal, convert it to a digital signal, and then convert it back to an analog signal, in a digital proximity system? The reason why Don Bently wanted to, is due to the restrictions on an analog proximity system. You can’t change the material type, the system length, or the probe type without errors in the linearity and accuracy of the proximity probe system. Bently knew eventually the technology would exist to allow for changes in the proximity system. Bently patented the first digital proximity in 1993, but he didn’t build it due to processor speed. Digital processor speed was just not able to overcome analog technology in 1993, that didn’t happen until 2012. In the meantime, Metrix did produce the first digital proximity system in 2005, the TXR/TXA, however, it wasn’t ready for high-speed turbo machinery. In 2012 Metrix created the Digital Proximity System (DPS), and then in 2016 Metrix fulfilled on the vision of Don Bently and created a field configurable DPS that was API 670 compliant for the full temperature range. We now have tens of thousands in operation around the world.

DPS Driver and Transmitter

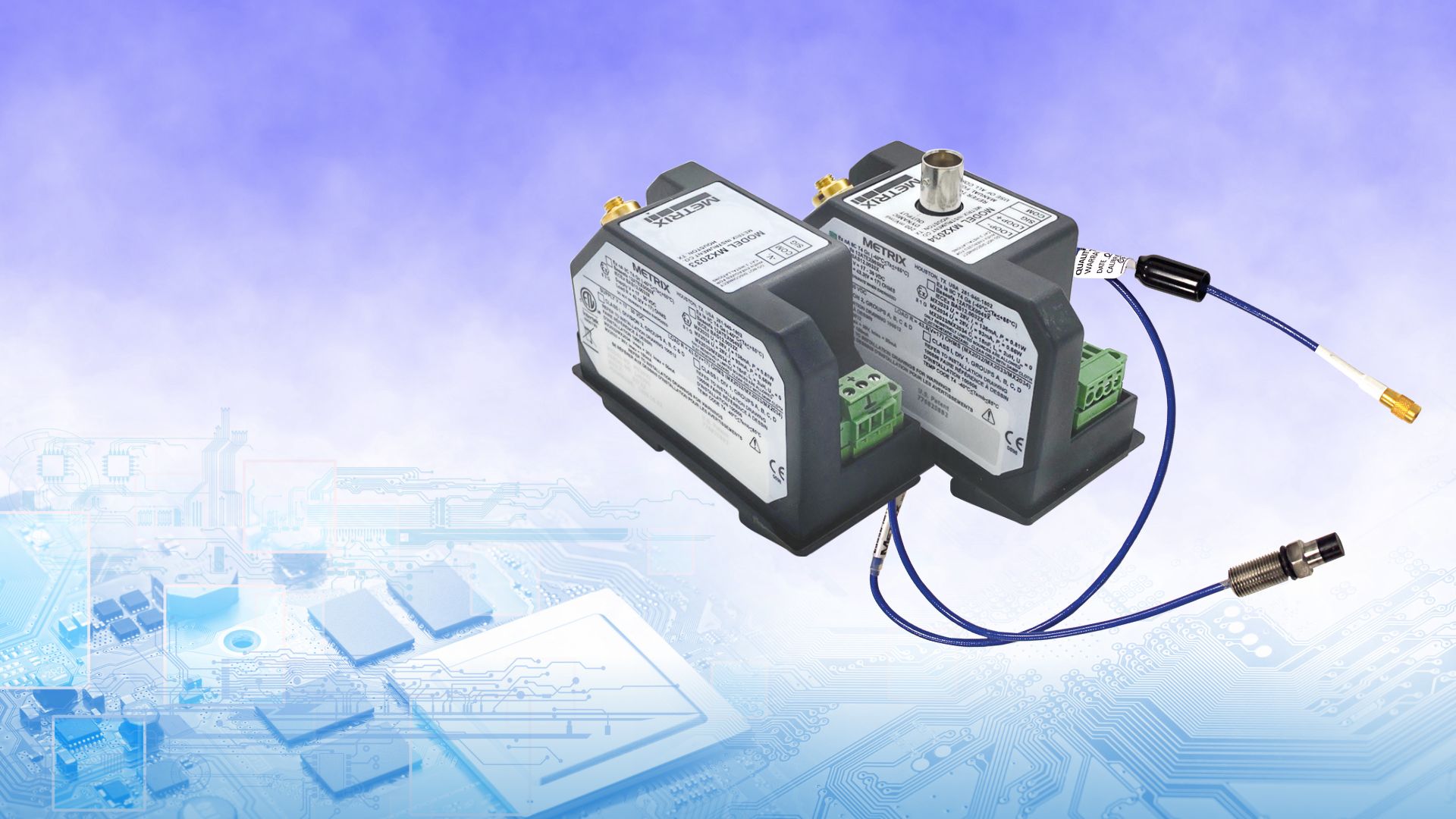

A driver or transmitter is available, depending on the required signal output format: the MX2033 3-Wire Driver is used with vibration monitoring systems and the MX2034 4-20 mA Transmitter is used with control systems, Programmable Logic Controllers (PLC) and Supervisory Control and Data Acquisition (SCADA) Systems. These models are fully compatible with a large variety of probes and cables from Metrix, BN, and other manufacturers.

The MX2033 Driver signal output is compatible with industry-standard continuous vibration monitoring systems and is in the format specified in API Standard 670. It uses -24Vdc excitation and provides the output signal in mV/μm, typically 7.87 mV/μm (200 mV/mil) or 3.93 mV/μm (100 mV/mil).

The MX2034 Transmitter provides a Static Current Output (mA/µm or mA/mil) and an optionable dynamic signal output. The MX2034 transmitter provides a scaled signal output for thrust, radial vibration, or shaft speed directly to PLCs, DCSs, SCADA systems, or other instrumentation that accepts an ISA Standard 4-20 mA signal, without the use of a separate monitor system. The transmitter is a +24 Vdc current loop powered device.

Proven Technology

The Metrix Digital Proximity System (DPS) combines the performance of a fully API 670 compliant eddy-current proximity measurement system with the flexibility of digital configurability. Users can configure their transducer system in the field using a custom field-generated curve as well as factory pre-configured calibrations for a variety of probe tip diameters, manufacturers, extension cable lengths, target materials, and linear ranges.

Real-World Examples

Metrix makes a variety of vibration equipment that uses the developments named above. Our customers count on us to save more than they spend, and we’re more than ready to meet their high expectations.

Methanol Producer

The site leadership of a methanol producer contacted Metrix after seeing a lot of downtime to a critical machine train. They suspected it was because of their lackluster vibration monitoring equipment, and they worked with Metrix to find a solution that would directly address the machine that was giving them so much trouble. They selected our impact transmitters, rod drop transmitters, and velocity transmitters after speaking with our team.

After the installation, personnel at the plant shared the data with Metrix so everyone could review it. It was determined that one of their impact transmitters was reporting a step change, which led to an investigation of the root cause. Ultimately, it was the valves on the compressor cylinder that were causing the problems. Once the producer replaced the valves, the transmitter output returned to normal and the unplanned downtime stopped.

Power Company

Metrix worked with a power company that had recently changed from coal to gas-powered boilers. They chose our digital proximity system to upgrade their existing systems and retrofit their pump trains. It was a good thing they did, because their equipment was decades old, and it needed to be outfitted with a solution that was flexible enough to both outfit and retrofit their operations. By using the latest advancements in technology, Metrix sensors have enough configuration settings to handle the wide range needed in the power plant. Plus, we were able to stay out of the way during the setup, so there was very little disruption to the staff. The customer thought the DPS was the perfect spare part, flexible, configurable, linear and accurate.

If you want the best possible performance from your equipment, take advantage of the Metrix Digital Proximity System. However, even if you’re not planning to upgrade soon, you should know how these systems have evolved over the past decade. If you're interested in how these systems can augment or replace your current systems, contact us today for more information.